We produce with %100 Costumer Satisfaction

principle.

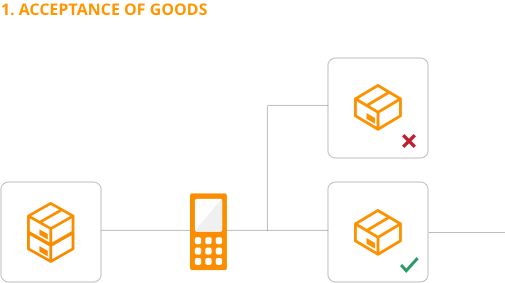

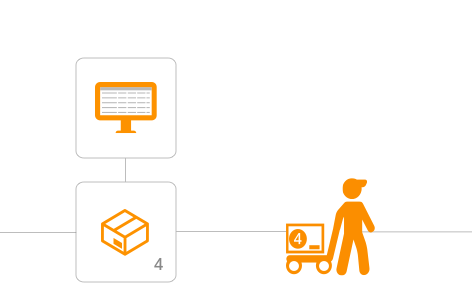

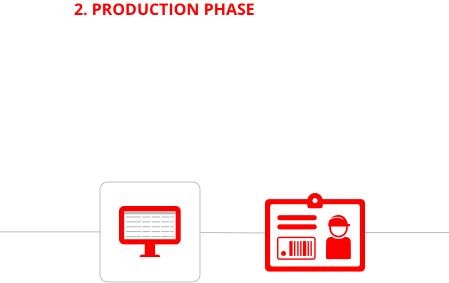

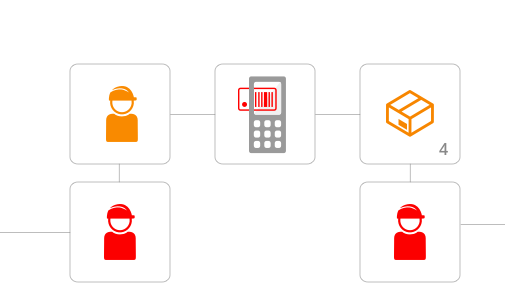

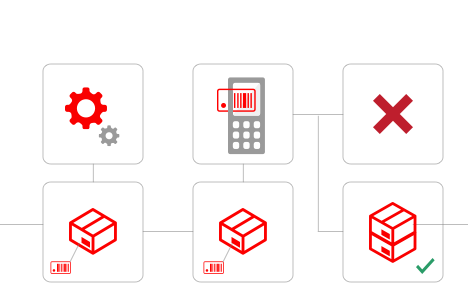

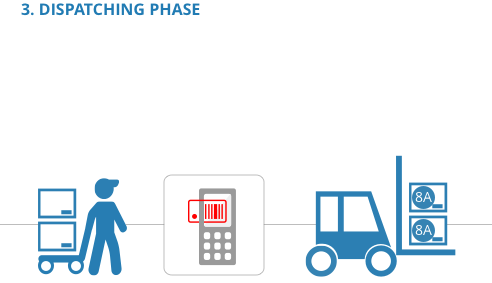

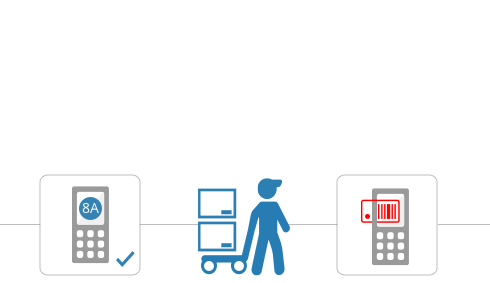

Traceability

We reduce the margin of error in production with

the quality control system which we apply in

all phases of the production process from raw material selection

to production and from packaging to delivery.

Quality Guarantee

You can share your complaints or suggestions with us for all the products you use and the ones that you are not satisfied with. Requests will be assessed sensitively and the products will be replaced with new ones free of charge if necessary.

As a result of your suggestions and complaints, the source of the problem related to the product will be identified and necessary precautions will be taken to prevent the problem from recurring. Although we did not need it until today; our ‘traceability’ system allows us to quickly and easily recall the product if any errors are detected in the controlled products (e.g. a health hazard or a serious problem) using replicate samples; it helps to withdraw an entire party from the market, if necessary.

You can easily inform your suggestions, requests and complaints via the Contact Form on our website.

Hygiene and Safety

Our procedures to ensure hygiene, health and safety for all our employees and our visitors;

Hygiene areas are used in the production and in the storage areas.

Hygiene areas are used in the production and in the storage areas.

Before entering the facility’s premises, our employees and our visitors should take out their jewelry such as watches, necklaces, earrings and brooches.

Before entering the facility’s premises, our employees and our visitors should take out their jewelry such as watches, necklaces, earrings and brooches.

Before entering the production area, visitors need to wear apron dress and the employees wear work clothes. First, they wear a bone, then an apron, and finally a shoe.

Before entering the production area, visitors need to wear apron dress and the employees wear work clothes. First, they wear a bone, then an apron, and finally a shoe.

The hands are disinfected after they are being washed and dried.

The hands are disinfected after they are being washed and dried.

We regularly carry out necessary analysis, examination and implementation in accordance with relevant Occupational Health and Safety (OSH) laws, regulations and communiqués in order to minimize and eliminate the health problems and professional risks that our team members may encounter due to reasons such as physical environment conditions and working environment.

We conduct our work in accordance with all rules and laws in order to ensure that the working conditions and means of production are sanitary and that our team members are protected from all the harmful effects of the working environment and to keep the social, psychological and physical health of our team members at the highest level.

Knowing that we are responsible for all actions, including Occupational Health and Safety;

- Risk assessments are regularly monitored throughout our workplace.

- Measures are taken to prevent any job accidents, occupational diseases and possible risks.

- We work in cooperation with Occupational Health and Safety Company and OHS professionals.

- Risk assessment is regularly carried out and necessary measures are taken in order to determine the hazards that may exist in the workplace and may come from outside.

- At the beginning of the work and during the working hours, health checks are carried out at regular intervals to determine the sensitiveness of our teammates and to identify risky situations.

- There is an emergency plan against first aid, fire fighting, serious and close threats. Trainings are held regularly and practices are conducted. The vocational training of our team members is repeated and documented at regular intervals. The duration of the training is counted as the working hours.

- There is an occupational health and safety board that carries out OHS related activities.

Laboratory & Tests

We meet the standards and durability of our products in accordance with international standards, including ASTM and TSE test methods, with state-of-the-art laboratory equipment and machinery in our facility.

Quality control tests during production;

Physical Tests: These include physical tests performed at each stage of the production process, such as visual control tests, physical measurement tests and the control of producer’s declarations.

Seal Thickness Test: Testing and verifying the thickness of each bag.

Bursting Test: This test is made by a burst machine, which checks the maximum pressure that the bags can withstand.

Seal Resistance Test: This test is used a tension test machine to measure the durability of the seals.

Leak (Blow) Test: This test is done by blowing air in the bags to understand the tears, cracks, wrinkles, etc.

Water Test: This test checks the water leakage of the bags.

Our devices are;

- Spectrophotometer

- Scales

- Drying Oven

- Ash Oven

- Seal Strength Machine

- Burst Testing Machine

- Dart Drop Machine

Documents and Certificates

For over 30 years, we continue to work in compliance

with Turkish and international standards, both with

the quality of our products and the understanding

of ethical work.

We have a Business Registration Certificate approved by the Ministry of Food, Agriculture and Livestock as a company operating in the production and processing stages of substances and materials that contact with food.

We have following certifications; ISO 9001: 2008, which guarantees that our products and services are manufactured in accordance with internationally accepted standards and guarantees the continuity of our product and service quality, ISO 22000, which demonstrates that we ensure the safety of the food chain, BRC Packaging which ensures that our compliance with safety and business standards, ISO 45001 for occupational health and safety, TSE EN 13592 certificate which determines the Plastic Bagging Standards for Collection of Household Wastes and in addition we are among the licensed companies working in cooperation with the ÇEVKO Foundation.

We are one of the organizations subject to the SEDEX audit, which states that all of our documents and certifications, as well as the owners, partners or managers of the organizations, act in accordance with the values of the community and act in accordance with the business ethics and law.